真空负压加载的电池组气泡及缺陷检测

Vakuum loading on battery packs

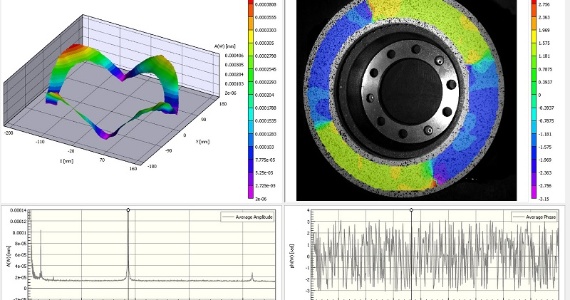

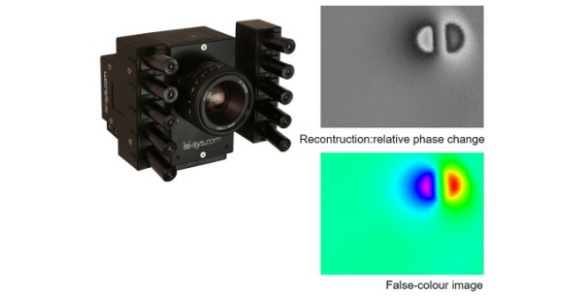

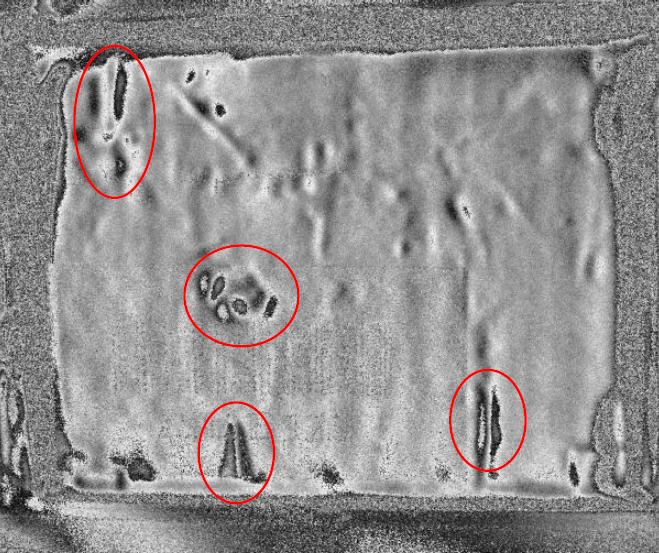

现代锂电池组中的气泡或气囊问题极为严重且危险。isi-sys SE2传感器能在1秒内检测到气泡、气囊、裂纹等大小缺陷,无论缺陷位于表面下方深处或近表面区域。下图展示了电池组实例(慕尼黑工业大学IWB实验室测试样本)及其测量结果。

测试装置:

本次测试采用SE2传感器配合玻璃真空腔室进行简易手动检测。该方案适用于人工操作的经济型点检式无损检测。生产中的自动化批量测试需配置不同装置。

测试流程:

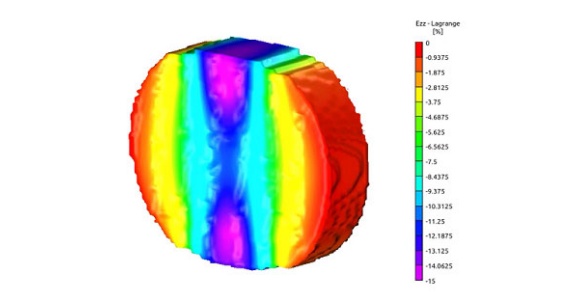

电池组在微米级压差环境下接受检测,微压腔室可在数秒内完成加压。传感器在压力变化过程中实时监测电池组表面,测量表面的差异变形。通过气泡和气囊的膨胀,可定位气泡位置,如下图所示。

首张图为传感器实时捕捉的电池组图像,第二张图为重建的相位图,对应局部变形梯度分布。

Air inclusion or air pockets in modern Li-battery packs is a serious and dangerous problem. The isi-sys SE2 sensor is able to detect tiny and large defects such as air bubbles, air pockets, cracks and other within a second. The defects can be far below or near to the surface. An example of a battery pack (test sample from University of Munich, IWB) and the measurement result is shown below.

Test setup:

The test has been done by SE2 sensor in combination with a glass vacuum chamber for a simple manual test. This is an economic solution for spot NDT by manual service. For automated series test in production different setups are required.

Test pocedure:

The battery packs are tested by small pressure differences of some mbar, which can be applied in seconds or below in small chambers. The sensor is monitoring the surface of the battery pack while the pressure is changed, measuring the differential deformation of the surface. Due to the expansion of the air bubbles and air pockets, the air inclusions can be located such as shown in the following images.

The first image shows the live view of the battery pack from the sensor. The second shows the recontructed phase, which is corresponding to the local deformation gradient.

通常所需的压差取决于缺陷深度、缺陷尺寸以及被测结构的机械刚度,但由于检测表面差分变形的传感器具有高灵敏度,因此施加的载荷通常较小。

Generally the required pressure difference depends on the defect depth, defect size an the mechanical stiffness of the tested structure, but in general the load is small due to the high sensitivity of the sensor detecting differential deformations of the surface.