风机叶片和树脂桥在动态载荷下的缺陷检测

Dynamic loading on a wind turbine blade and resin bridges

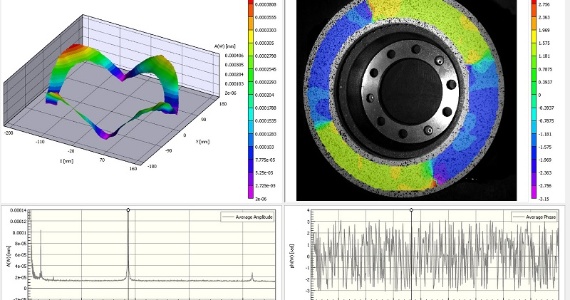

风力涡轮机叶片分析 Analysis of a wind turbine blade

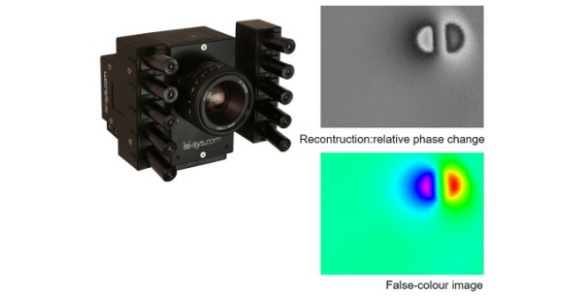

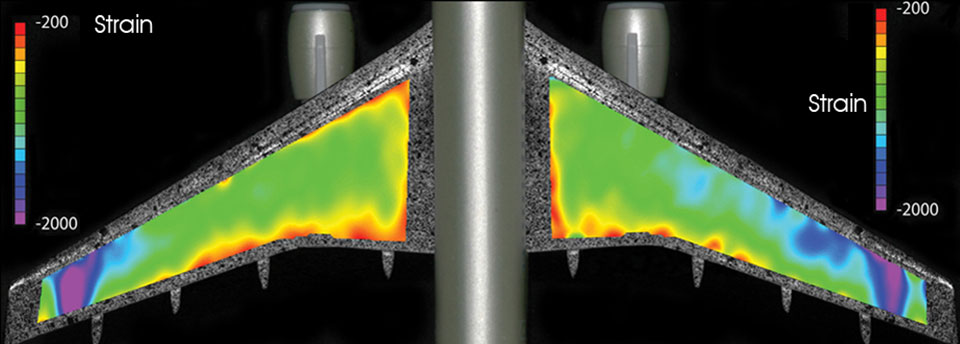

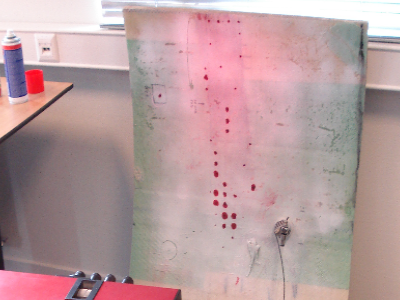

测试面板为带缺陷(带桥接结构的泡沫块)的风力涡轮机叶片原始截面。此前通过在钻孔处注入染料定位该缺陷。本样品采用SE传感器进行无损检测。

The test panel was an original section of a wind turbine blade with a defect (a foam block with bridges). Previously the defect was located by infiltration of color through small drilled holes. The sample is examined non-destructively by the SE-Sensor.

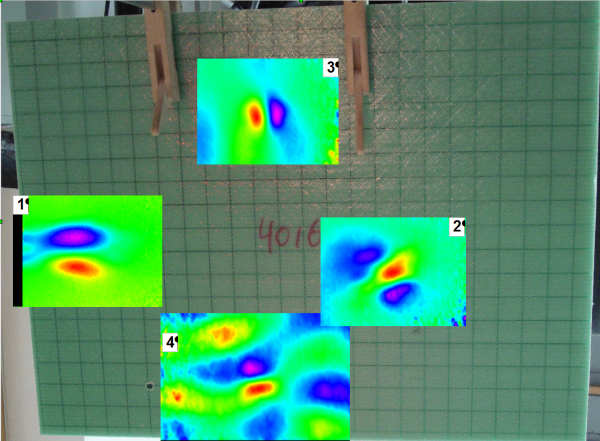

左:试验设置

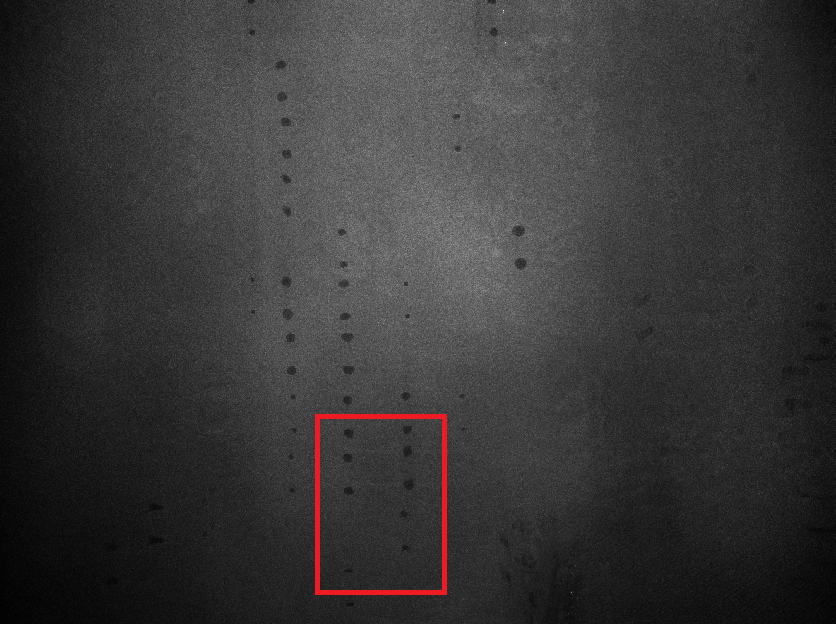

右:2569Hz频率下的时间平均结果,显示脱粘区域。

left: Set-up

right: Time average result at frequency of 2569Hz showing the debonding area.

左:包含剪切现象的表面实时视图。

右:实时图像中标记区域的时间平均测量结果。

left: Live view of surface including shearing.

right: Time average measurement from the marked area in the live image.

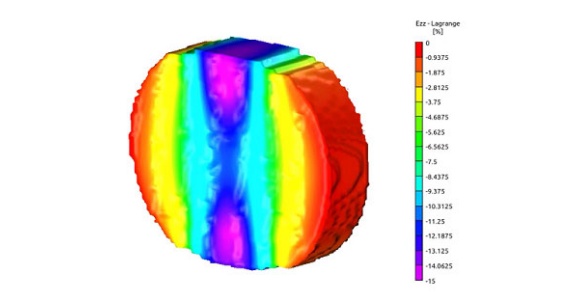

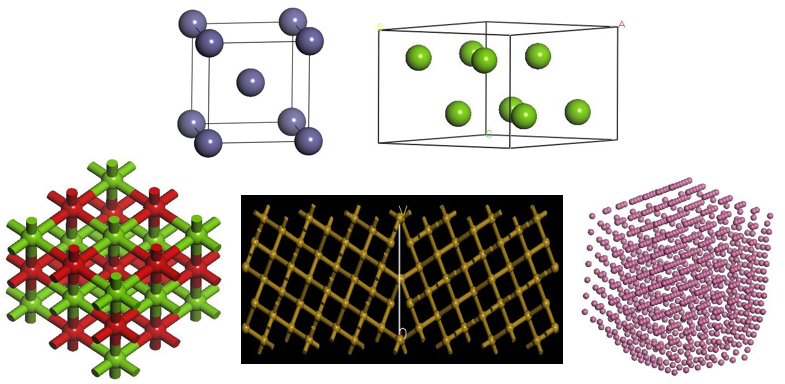

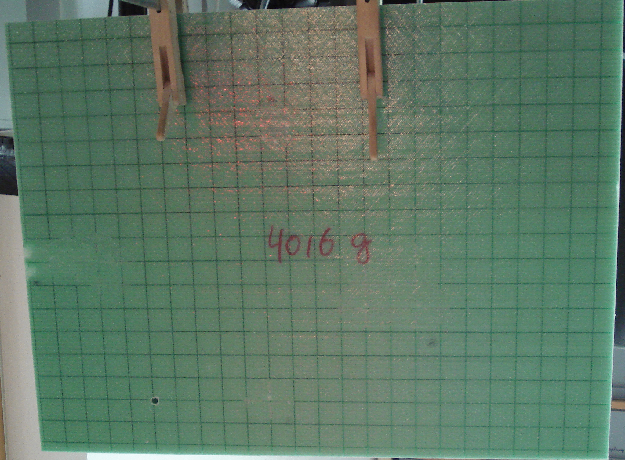

树脂桥接头的脱粘现象 De-bonding of resin bridges

需检测含泡沫块与树脂桥接头的玻璃纤维增强塑料夹层结构。此类缺陷的类型与结构检测极为迅速可靠,因其不仅在局部固有频率下可见,更可在宽频带范围内通过受迫变形形态清晰呈现。

A GFRP sandwich with foam blocks and resin bridges should be examined. The detection of the defect type und structure is very quick and reliable in this case, because the defects are visible, not only at their local natural frequencies, but also due to their forced deflection shapes over a wide frequency bandwidth.

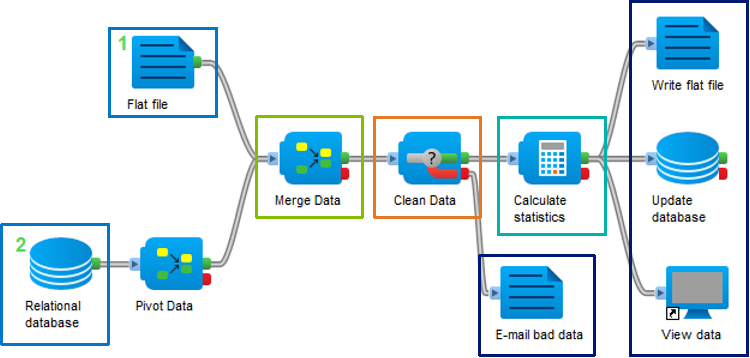

所选测量的激励频率分别为1398 Hz(1)、3133 Hz(2)、2442 Hz(3)和4906 Hz(4)——后续图像中的编号如下:

The excitation frequencies of the selected measurements are 1398 Hz (1), 3133 Hz (2), 2442 Hz (3) and 4906 Hz (4) — numbering in following images: