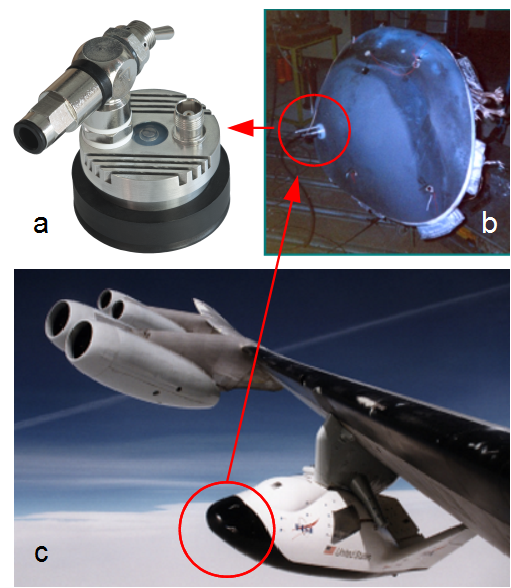

NASA X-38再入式航天器机首整流罩缺陷检测

Dynamic excitation on a spacecraft

2000年历史测量数据

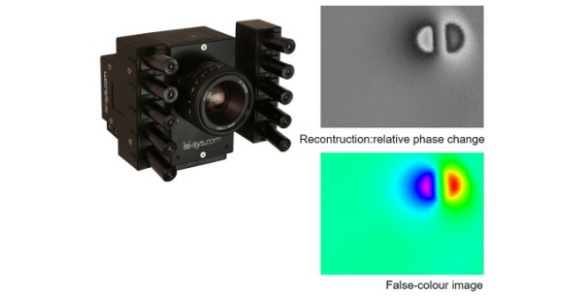

本案例将振动成像系统与压电振动器模块结合用于无损检测。通过剪切成像技术对未来回收飞行器/航天器x38搭载的碳纤维硅复合材料(C-Si-C)隔热罩进行了检测。

Historic measurement from 2000

This example combines the Vibrografie System with a Piezoshaker Module for a non-destructive inspection. The heat shield with C‑Si‑C (carbon fiber-silicon composite) of the prospective recovery vehicle/ spacecraft x38 was reviewed by Shearography.

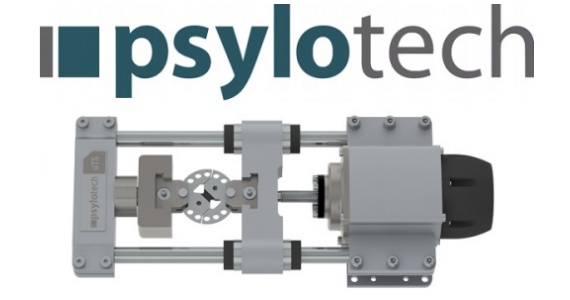

为便于操作,压电振动器模块通过吸盘基座紧贴物体表面。

(a) 压电振动器模块,(b) X38航天器隔热罩 © X38航天器飞行实景。

For easier handling, the Piezoshaker module is compressed on the surface of the object via a suction base.

(a) Piezoshaker module, (b) the heat shield of the spacecraft X38 © Flight of the spacecraft X38.

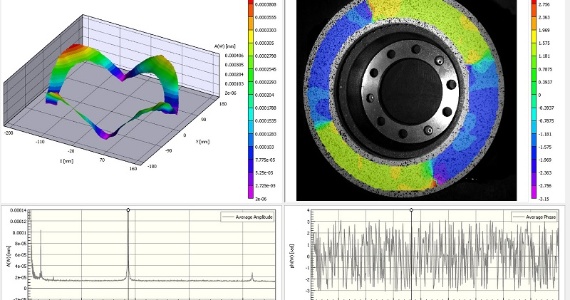

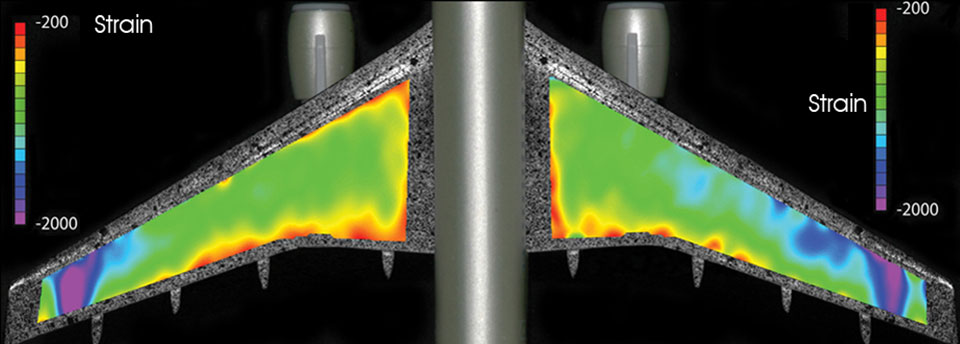

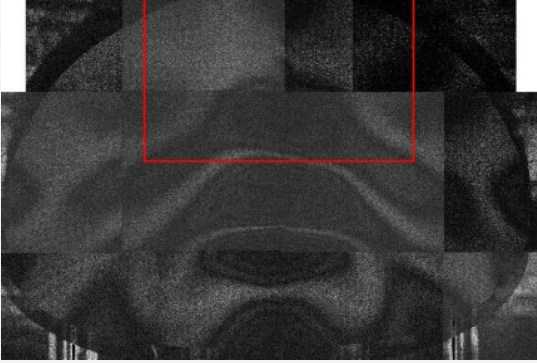

该图展示了具有自然频率(1400 Hz)的隔热罩的时域特性测定。

The picture shows the determination of times of the heat shield with the natural frequency (1400 Hz).

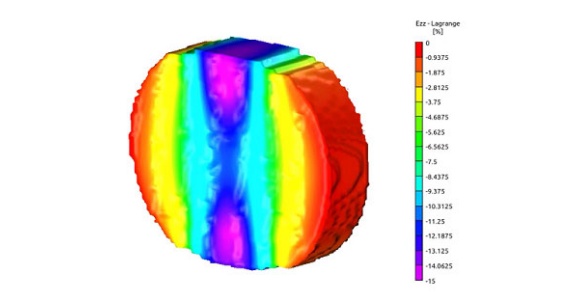

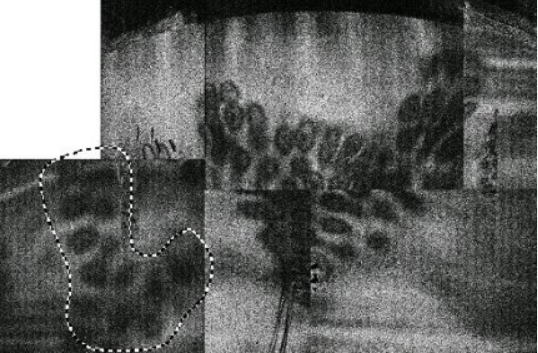

图像标记区域内机头罩在10kHz和18kHz频率下的局部振动缺陷形态。检测过程中,在机头罩上部区域发现了两个缺陷。

Local vibration forms of defects at 10kHz and 18 kHz of the nose hood in the marked area of the image. During the inspections, two defects have been detected in the upper area of the dog.