风电叶片的无损检测

NDT on Wind Rotor Blades

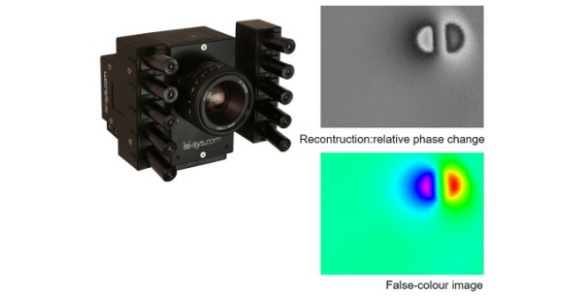

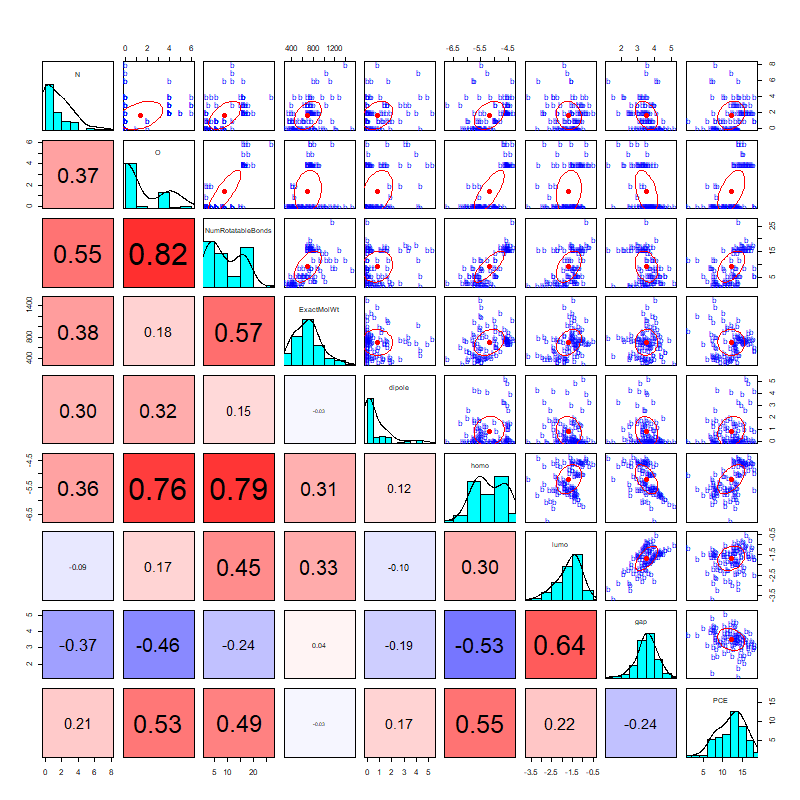

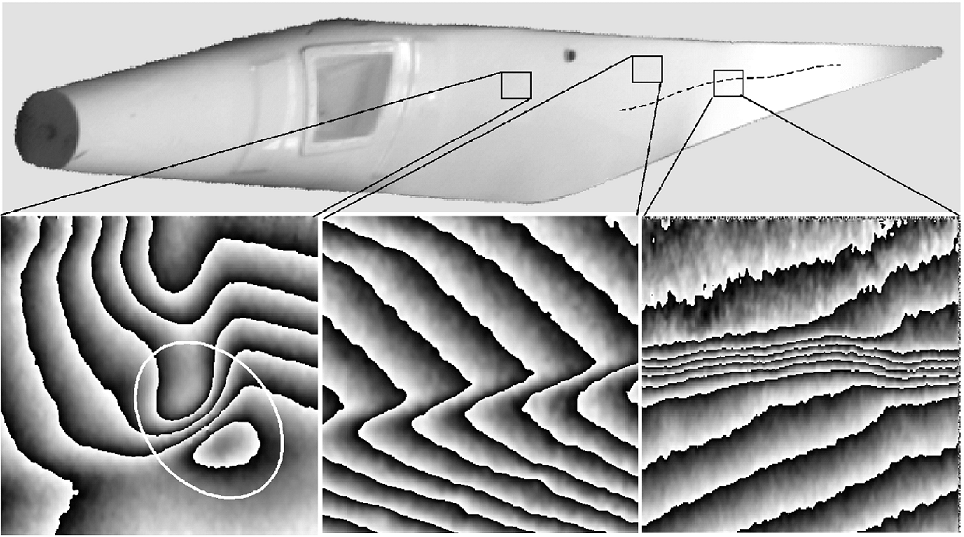

1996年,卡塞尔大学的P. Mäckel、L. Yang、G. Kupfer和A. Tiemich首次对风力涡轮机叶片进行剪切成像无损检测测量。该物体为单翼风力发电机组的特殊风轮叶片。

First test NDT Measurement by shearography on a wind turbine blade in 1996 by P. Mäckel, L. Yang, G. Kupfer and A. Tiemich at Kassel University. The object is a special wind rotor blade of a single wing wind turbine energy plant.

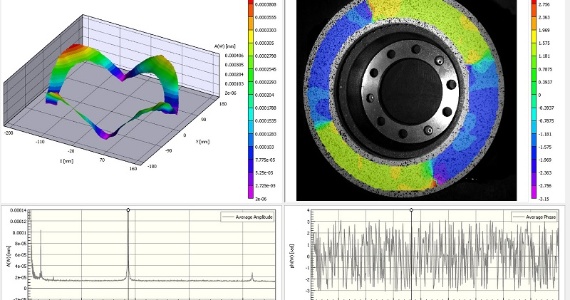

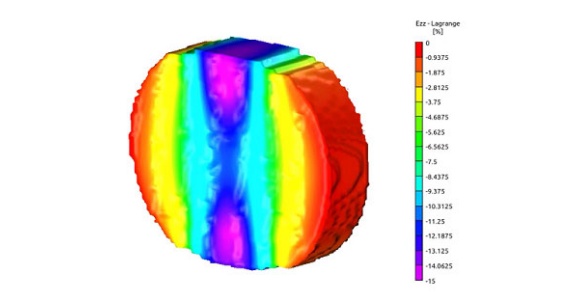

施加载荷方法:通过内压加载(叶片已密封)。采用手动泵建立与周围环境的压差。干涉条纹图像显示不同位置的区域。条纹强度与表面面外变形梯度成正比,可据此识别结构的非均匀刚度:左侧——分层;右侧——轴向裂纹;中央——结构变化区(玻璃纤维层数不同)。

Applied loading method: Loading by internal pressure (the blade has been sealed). A manual pump has been used to increase a pressure difference against the surrounding. The fringe images show areas at different locations. The fringes are proportional to the out of plane deformation gradients of the surface, which allows to identify inhomogeneous stiffness of the structure: left — Delamination; right — Axial crack; center ‑Structural change over (different number of glasfiber layers).