大型游艇船体在动态加载下的缺陷检测(碳纤维-NOMEX(蜂窝芯)复合材料无损检测)

NDT of Carbon-NOMEX (honeycomb core) composite: Dynamic loading on a large yacht hull

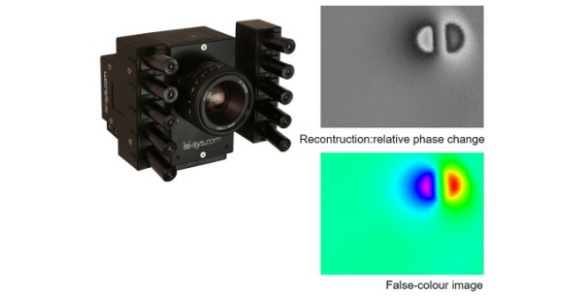

西班牙Marine NDE公司利用isi-sys复合材料与结构缺陷激光无损检测系统的技术优势,结合动态激励技术,完成了对一艘在建高性能游艇船体的全面无损检测。该船体长30.5米,采用碳纤维复合材料与NOMEX蜂窝芯的夹层结构,检测团队通过全域检测方法(检测区域100%覆盖),仅用240次拍摄、3个工作日即完成全船检测。

PS:以上信息基于上一代SE2传感器实际检测数据总结,全新一代SE4传感器具有数倍于该传感器的检测效率。

Marine NDE (Spain) used the technical advantages of our Shearography-System especially in combination with the dynamic excitation for non-destructive examination (NDE) of large areas such as complete yacht hulls (see image below). The hull with a lenghts of 30,5m was a carbon-firber-composite and part of high performance sailing yacht in build. Because of the full-field method (100% of the inspected area is examined), the testing of the entire hull required only 240 shots, in three workdays.

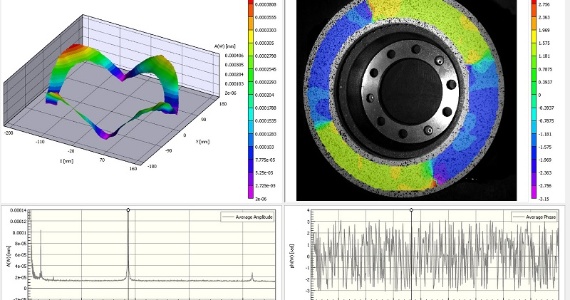

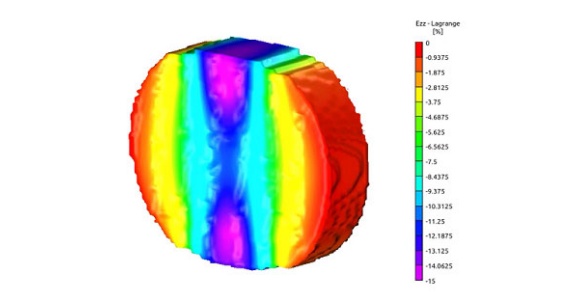

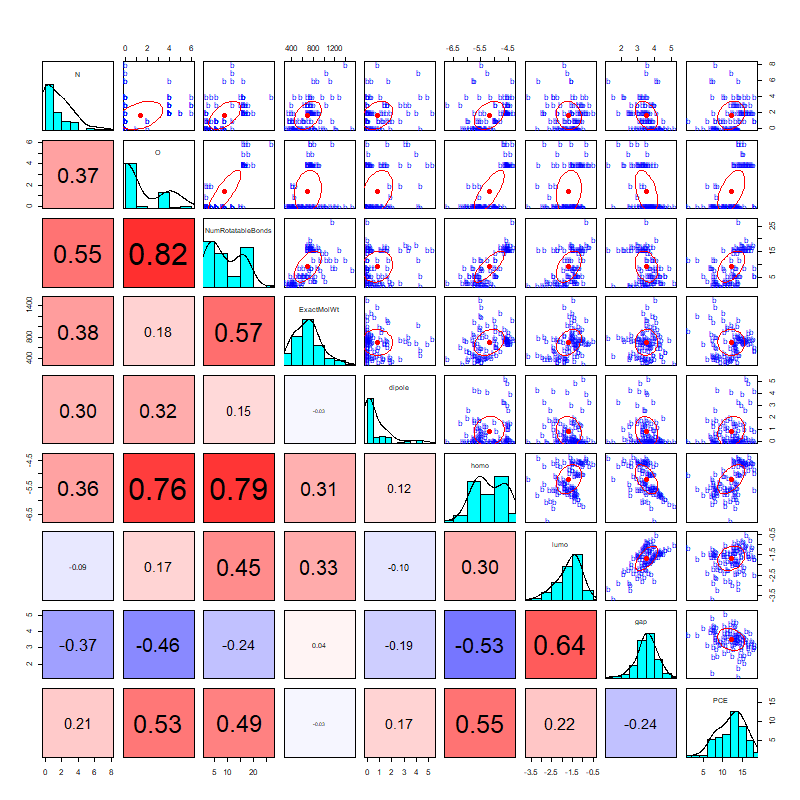

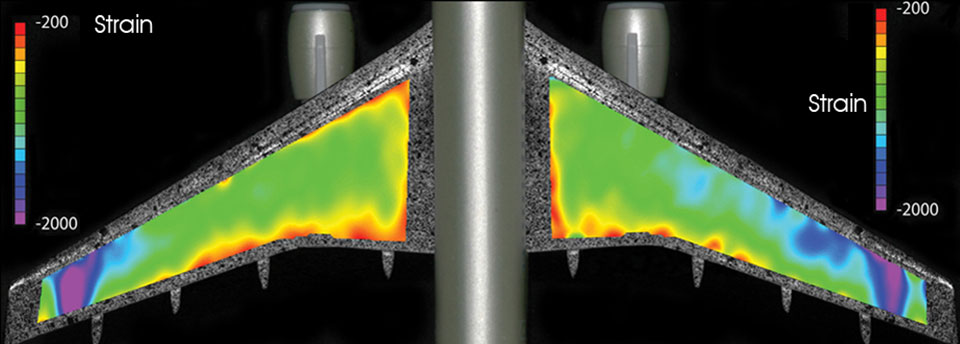

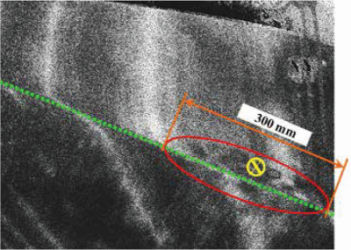

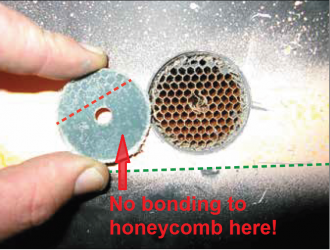

检测中发现一处蜂窝芯材料与薄膜的显著未粘合缺陷(如下图红色椭圆标识),并通过破坏性取样验证了检测结果的准确性(左图黄色X标识了右图所示芯材样本的取样位置)。这一案例验证了激光无损检测技术在大面积复合材料检测中的高效性——传统点检测方法需数周完成的工程,通过全域动态加载技术可大幅缩短检测周期。

The yacht hull consists of a sandwich construction, where are in particular used honeycomb cores (NOMEX).

On the left — A shearogram of a detected bonding defect (in red oval). The yellow X marks the location of the core sample shown at the right. The destructive test confirms the shearogram’s indication that there is a significant never-bond between the honeycomb core material and the film adhesive in this area.