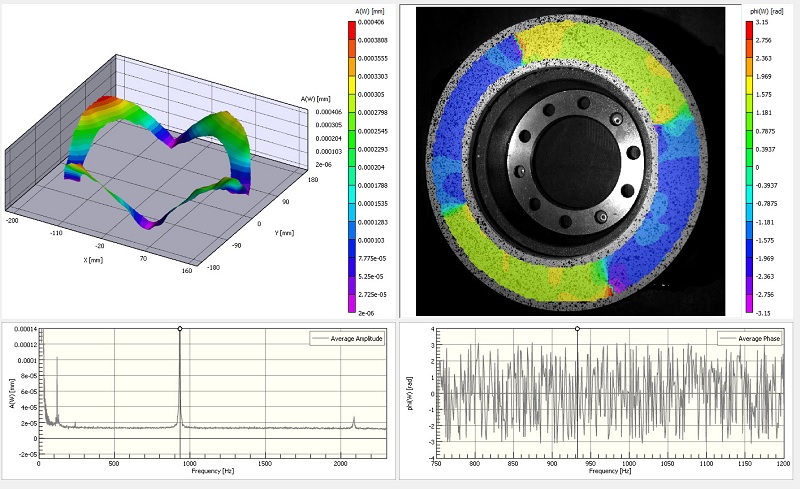

During correlation and optional post-processing, Vic presents a wide range of output data available for 3D and contour plotting, extraction, and export. This application note gives an overview of commonly presented variables.

Output Variables

Always Present

- X [mm] – metric position along the X-axis (by default, the horizontal axis).

- Y [mm] – metric position along the Y-axis (by default, the vertical axis).

- Z [mm] – metric position along the Z-axis (by default, the out-of-plane axis).

- Sigma [pixel] – the 1-standard deviation confidence in the match, in pixels. 0 indicates a perfect match; higher numbers indicate a noise, excessive gradients, or possibly a failed match.

- U [mm] – metric displacement along the X-axis, from the reference image. For the reference image, this value will always be 0.

- V [mm] – metric displacement along the Y-axis.

- W [mm] – metric displacement along the Z-axis.

- x [pixel] – the X location, in the raw image, of the data point,

- y [pixel] – the Y location, in the raw image, of the data point.

- u [pixel] – the raw X-axis displacement between the reference image and a given image, in pixels. This is an internal variable which feeds into the triangulation algorithm to generate the 3D metric displacement data. Effectively, this variable is the output of a 2D correlation between the reference camera 0 image and the deformed camera 0 image.

- v [pixel] – the raw Y-axis displacement between the reference image and a given image, in pixels.

- q [pixel] – the raw X-axis disparity between the camera 0 image and camera 1 image, in pixels. This is an internal variable which feeds into the triangulation algorithm to generate the 3D metric shape data. Effectively, this variable is the output of a 2D correlation between the reference camera 0 image and a given camera 1 image.

- r [pixel] – the raw Y-axis disparity between the camera 0 image and camera 1 image, in pixels.

- q_ref [pixel] – this is the same as the computed X-axis disparity but is reserved for the software and cannot be edited by the user. This variable is used for retriangulation.

- r_ref [pixel] – the reserved Y-axis disparity.

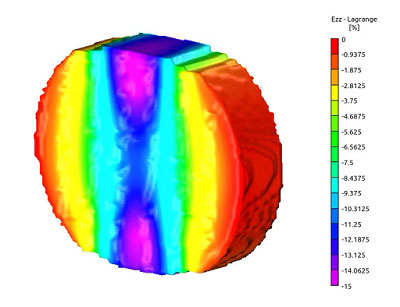

Strain Variables

- exx [1] – strain in the X-direction. Positive numbers indicate tension; negative numbers indicate compression.

- eyy [1] – strain in the Y-direction.

- exy [1] – shear strain.

- e1 [1] – the major principal strain.

- e2 [1] – the minor principal strain.

- gamma [1] – the principal strain angle, measure counterclockwise from the positive X-axis.

Velocity Variables

- dU/dt [1] – the rate of change of the U-displacement; that is, the velocity of a given point in the X direction.

- dV/dt [1] – velocity in the Y direction.

- dW/dt [1] – velocity in the Z direction.

- dExx/dt [1] – the rate of change of strain in X, or strain rate in X.

- dEyy/dt [1] – the strain rate in Y.

- dExy/dt [1] – the shear strain rate.

- Note: principal strain rates are not calculated because principal strains, by nature, do not have a consistent reference frame from one image to the next.

Confidence Margins

- Sigma_X [mm] – the 1-standard-deviation (67%) uncertainty in the X-axis.

- Sigma_Y [mm] – the 1-standard-deviation (67%) uncertainty in the Y-axis.

- Sigma_Z [mm] – the 1-standard-deviation (67%) uncertainty in the Z-axis.

2D-Specific Variables

- x_c, y_c, u_c, v_c - these variables appear in the extraction dialog. If a scale calibration is present, they represent the scaled position and displacement. If no scale calibration is present, they're equal to the pixel values.

Deformed Variables (export only)

- Xp – the deformed X value, equal to X+U. This is an option in the export dialog and is added for convenience.

- Yp – the deformed Y value, equal to Y+V.

- Zp – the deformed Z value, equal to Z+W.